Blog

Gypsum Underlayment Repair: When to Restore vs. Replace

Gypsum underlayments—especially older installations in multifamily renovations—often suffer from a soft, chalky texture, surface cracks, and inadequate compressive strength. These issues compromise adhesive performance, visual quality, and durability under stress. Rather than defaulting to demolition, a systematic evaluation can save time, labor, and cost.

Step 1: Diagnose the Damage—Restore or Replace?

Start with a careful assessment:

- Surface characteristics: Is the gypsum soft, chalky, porous, or crumbling? Does it prematurely absorb moisture from adhesives before it can bond as intended or show visible defects that can telegraph through finished flooring?

- Structural integrity: Many older gypsum underlayments fall well below today’s tile/luxury vinyl plank minimum compressive strength requirements (typically ≥3,000 psi). Some older gypsum slabs may test under 1,000 psi.

- Underlying substrate issues: Poor original installation, moisture exposure, excessive deflection (<L/360), compromised acoustical mat or structural faults should be addressed before any repair. Replacing gypsum alone won’t resolve root causes.

Step 2: When Restoration Is a Safe Bet

Consider restoration if:

- The gypsum is mostly intact and not severely weakened.

- Issues are confined to surface deterioration— hairline cracks, dusting, and minor soft zones.

- There are no fundamental structural problems or failed substrates.

In these scenarios, repairs with FloorPrep products offer an effective, code-friendly path forward.

FloorPrep Solutions for Gypsum Restoration

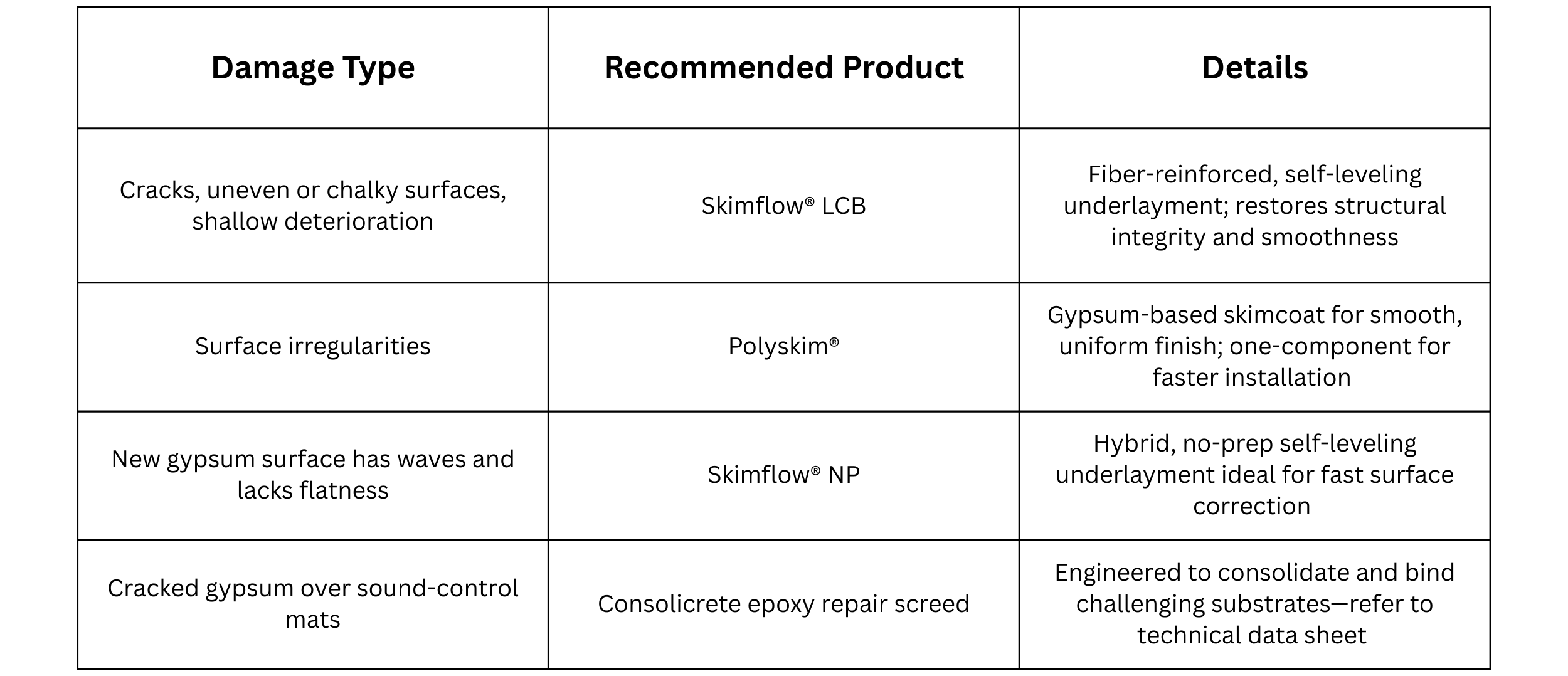

FloorPrep by Dependable offers specialized products tailored to different levels of gypsum damage:

Best Practices for Repair

- Ensure structural performance—confirm subfloor meets serviceability (e.g., L/360 deflection standards); involve a structural engineer if needed.

- Clean and prepare the surface—vacuum dust, debris, and loose material.

- Prime properly—use GSL Sealer, Primer P360, or PrepPro SLV (using recommended dilutions and procedures on product data sheets) to seal the porous gypsum, applying two thin coats, allowing penetration and drying between each coat. Perform a “tape test” after drying to ensure adhesion.

-

Apply repair material—choose between a skim coat or self-leveler based on damage. Follow manufacturer guidelines on mixing, application, and minimum required thickness.

- Ensure structural performance—confirm subfloor meets serviceability (e.g., L/360 deflection standards); involve a structural engineer if needed

- Maintain fire rating compliance—use only UL-rated products appropriate for fire-rated gypsum underlayment systems. Non-rated materials may void certifications and compromise safety

When Replacement Is the Better Option

Choose replacement over restoration if:

- The gypsum’s compressive strength is drastically below specifications (e.g. <1,000 psi) and unable to support hard surface adhesives and finished flooring even after priming.

-

Damage includes extensive cracking, pervasive crumbling or material loss.

- Structural substrate is compromised—deflection, excessive cracking, moisture injury, or poor initial installation that undermines longevity.

- Fire-rating compliance would be jeopardized by non-rated repair materials or improper installation.

In these cases, removing the old gypsum and reinstalling with structurally sound, properly UL rated underlayment is the safer route.

Summary: Restore When Feasible, Replace When Necessary

- Conduct a thorough evaluation to determine gypsum condition.

- Restore when damage is limited to surface deterioration and structure remains sound.

- Use FloorPrep’s suite—Skimflow LCB, Polyskim, Skimflow NP, or Consolicrete—to perform durable, compliant repairs.

- Opt for replacement if integrity, strength, or code compliance is in doubt.

By prioritizing restoration where feasible—and doing it right—you avoid unnecessary demolition, get projects back on schedule, and ensure performance standards are met.

Next Steps for Contracting Teams:

- Explore floorprep.com for detailed product specifications, technical data sheets, and UL compliance documents.

- Contact Dependable Technical Services for support on unique repair scenarios of fire-rated assemblies.

Let FloorPrep be your go-to resource for smart, efficient gypsum subfloor repair solutions—restoring performance without tearing it all out.